IPCS |

International Programme on Chemical Safety |

Safety

and Health in the Use of Agrochemicals

Safety

and Health in the Use of Agrochemicals

An ILO contribution to the

International Programme on Chemical Safety

(a collaborative programme of the United Nations Environment Programme the International

Labour Organisation and the World Health Organization)

Agrochemical users must make every effort to use those products that minimise the risk to themselves and others. In the choice of agrochemicals they may often be guided by advertisements in the mass media. It is therefore important that users seek advice from agricultural extension workers and several independent suppliers.

Similarly, choice of safe technology is important. For example, there may be several types of spray equipment on the market, but the cheapest ones are often not the best for safety. They may be of poor quality and might start to leak. The same may be true of the choice of personal protective equipment. Again, users should remember to seek advice.

The adoption of safe working systems and practices will minimise risk. Some of these have already been discussed in sections 2.3.6 and 2.3.7. The arrangement of working time, particularly in hot climates, would be relevant here. For example, agrochemical spraying could be undertaken in the early hours of the morning. Engineering control measures, personal hygiene and other measures, the use of personal protective equipment as a last line of defense and the alternatives to agrochemicals will be discussed in the following subsections.

2.4.1. Engineering control measures

A basic principle of user protection is that all possible measures should first be

taken to reduce exposure at the source. Routine maintenance should ensure that

agrochemical application equipment is in good condition and without any potential to leak

or spill. Particular attention should be given to knapsack sprayers where leakage could

seriously contaminate the user.

New developments in engineering controls go much further by introducing improved design features which automate agrochemical handling or make some tasks easier or safer. Examples of engineering control measures include:

Figure 32. Flow diagram of a field sprayer fitted with a pesticide induction bowl

Figure 33. A user wearing

protective clothing and

filling a pre-mix bowl on a crop sprayer washed after use

Personal hygiene aims to keep the body clean and not allow anything harmful to remain on it for long periods as it can be absorbed through the skin. It is equally important to avoid inhaling or ingesting small, even minute, quantities of agrochemicals because of their harmful effects on health.

The basic rules of personal hygiene in using agrochemicals are as follows:

Figure 34. Thoroughly wash exposed parts of the body

Figure 35. Personal protective clothing should be washed after use

There are other hygienic measures to be observed:

2.4.3. Use of personal protective equipment

Most agrochemicals present a risk to the user which may be controlled by engineering control measures. Where recourse to the above measures does not suffice, personal protective equipment should be used.

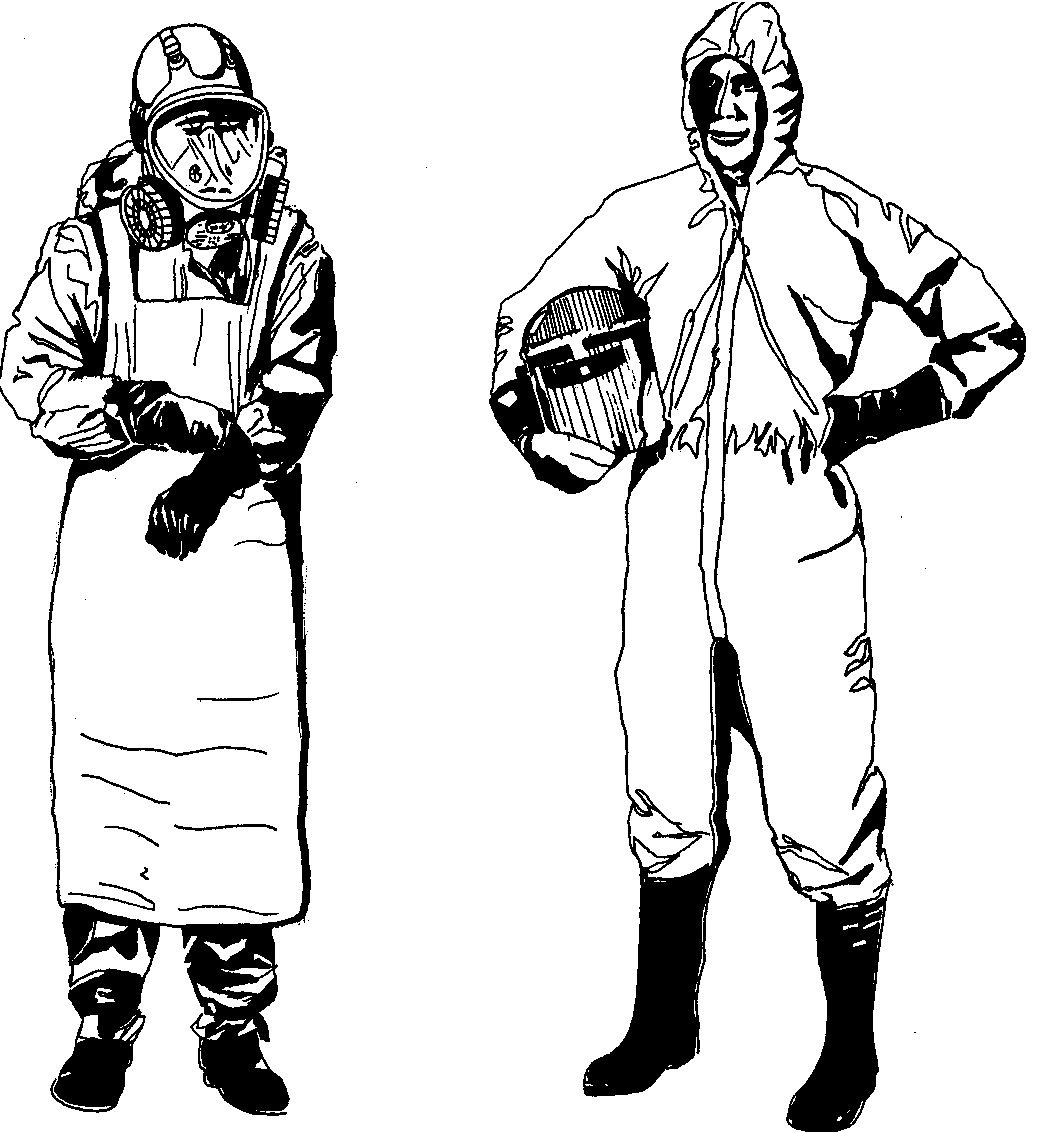

Because of the nature of farm work, engineering control measures may not always be feasible. Protective clothing therefore remains a necessary part of working with agrochemicals. The items required will depend on the harmful effects of the agrochemical and the way in which it is used. In practice, labeled information supplied with the agrochemical will generally specify the level of protection required. Detailed information on the quality of various items such as the minimum thickness of gloves or the material from which they are made, e.g. neoprene, nitrile or butyl, may also be supplied. Similarly, prescribed items of respiratory protective equipment and the care necessary in their maintenance might be listed. Examples of personal protective clothing are given in figure 36, and clothing and equipment necessary when working with highly toxic agrochemicals are shown in figure 37.

Figure 36. Examples of personal protective equipment

Goggles (for eye protection) Headgear Headgear Gauntlet gloves Gauntlet gloves |

Respiratory

protection Head, eye and face protection Head, eye and face protection |

Figure 37. Examples of protective

clothing and equipment for work with highly toxic chemicals

Full-faced respiratory protection

Coverall

Boots (worn outside coverall)

Head protection may be provided as a single garment or as part of a coverall or of a face shield with hood. The advantage of such a combined garment is to ensure protection around the neck or to prevent agrochemicals spilled on the hood from soiling the work clothing worn underneath. Head protection should cover all parts of the head above the shoulders, with the exception of the face. The material used should be resistant to penetration by agrochemicals.

2.4.3.2. Eye and face protection

A face shield covering the whole of the forehead and face to a point below the jaw should be worn to protect against accidental splashes of dangerous liquids during opening or pouring from containers. Non-fogging goggles resistant to chemicals should be worn when handling dusts or granules.

2.4.3.3. Respiratory protection

Respirators may be half-faced, covering nose and mouth, or full-faced, covering nose, mouth and eyes. Their function is to prevent the wearer from inhaling hazardous agrochemicals. A filtering, medium on the respirator removes the hazardous substances by absorption, adsorption or simple filtration. Filtration is by a simple gauze pad. In the case of highly hazardous agrochemicals, the air is filtered through a cartridge or canister containing other chemical substances that would absorb or adsorb the highly hazardous agrochemicals. Good respirators are manufactured to comply with national standards in several countries. The user should, however, ensure that the respirator provides a good fit around the nose and mouth and that he or she has received sufficient information and training on correct use and maintenance. The cartridges must be renewed periodically and the masks must be replaced regularly to ensure protection.

Gloves are required when handling concentrated agrochemicals, particularly pesticides. These are very commonly absorbed through the skin or cause damage to the skin by burning. They should be at least 0.4 mm thick while retaining flexibility for -simple manual tasks such as opening containers or changing nozzles. The type of glove for a particular operation will depend on the agrochemical and the length of time in contact. For example, gloves of wrist length may be required for conventional spraying of toxic pesticides, elbow length for handling granules, and shoulder length for dipping plants in pesticides. A pesticide formulation with organic solvents such as xylene will require a glove of much higher-quality material because of its capacity to penetrate protective garments.

An indication of protective glove performance when tested against three groups of agrochemicals is given in Annex D.

Working clothes are items of personal clothing worn at work, while using agrochemicals, in this instance. They include such items as shirts, trousers,, skirts, socks and shoes or boots. There will be many occasions when working clothes will be the main skin covering, e.g. when using low risk products or treating an animal.

Working clothes used at work with agrochemicals should be kept clean by washing immediately after use. Wearing clothes contaminated with agrochemicals: may result in poisoning or skin irritation. There have also been cases where flammable substances, such as sodium chlorate, deposited on clothes have ignited during cigarette smoking to engulf both clothing and the wearer in flames.

In general, working clothes should:

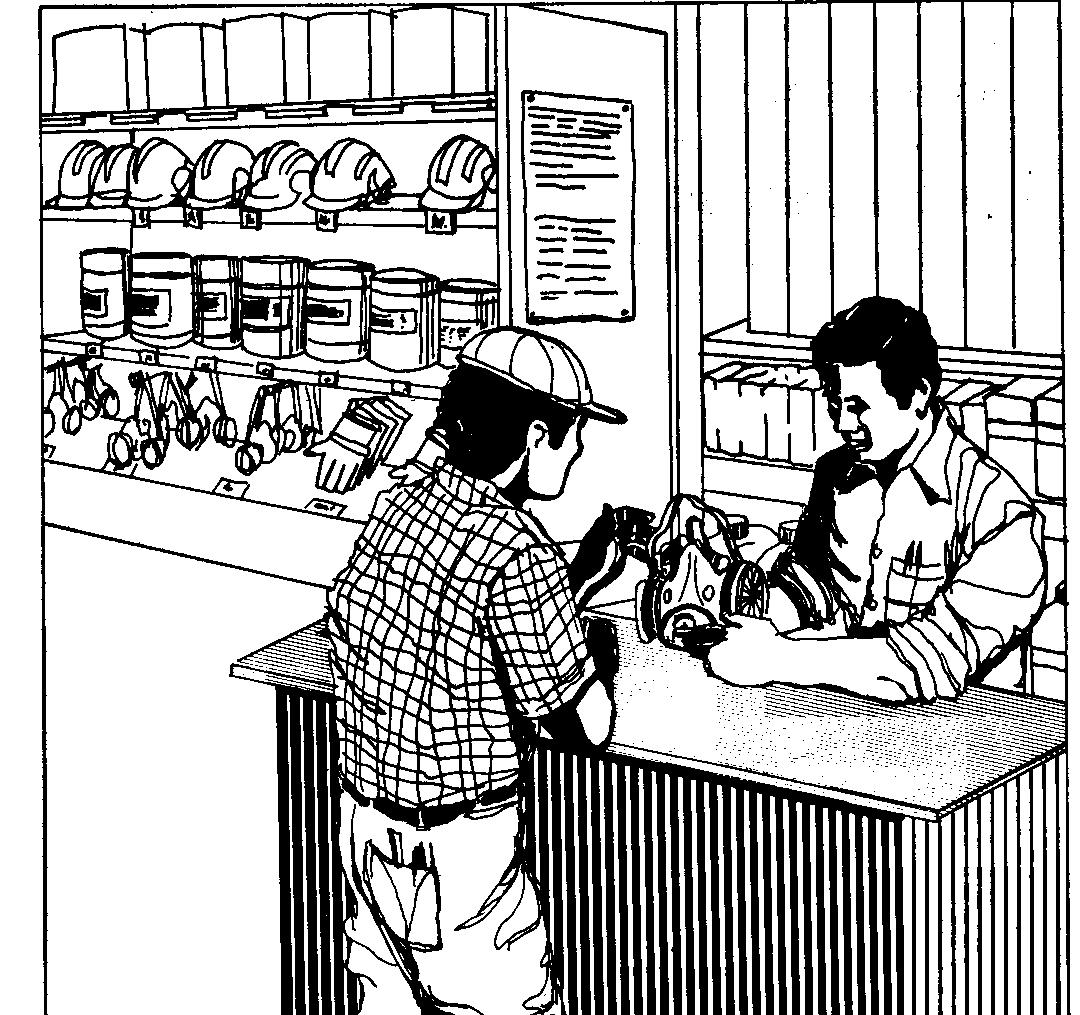

2.4.3.6. Selection, use and maintenance of personal protective equipment

When specified on the product label, the selection of appropriate personal protective equipment, its use and maintenance are essential for the protection of a person using hazardous agrochemicals. Advice should be sought (figure 38) and particular attention paid to the following:

Figure 38. Select the appropriate

type of personal

protective equipment (ask someone who knows)

Tailoring. Garments should preferably be made to measure, or ready-made ones should be well selected so that seams or welded joints do not pull apart or allow liquids to enter through stitch holes. There should be no trap points which hold agrochemicals and all pockets should be inside the garment or absent altogether. Garments should provide a good cover to those parts of the body which they are intended to protect. They should also allow freedom of movement to the wearer.

Correct matching. In practice, several items of protective clothing are often worn at the same time. Each should be a correct match with the other in providing continuity of protection between, for example, a hood overlapping the shoulders of a coverall, the sleeves of the coverall overlapping gloves, and an apron overlapping boot tops.

User friendliness. Protective

clothing should not prevent the wearer from carrying out the necessary tasks associated

with agrochemical- work. Gloves should not be so big or rigid that the fingers cannot be

manipulated to replace a sprayer nozzle. It should be possible for the wearer to move

freely without being hindered by the sheer bulk or poor design of any garment. Similarly,

garments should not be unduly heavy or hot when worn. Those for use in tropical countries

should wherever possible be of lightweight material and coloured white or yellow so as to

reflect heat. Users should learn how to select the appropriate protective equipment.

Washabifty. All garments used at work with agrochemicals: should be washable

without any substance being retained in "trap points". Absorbent garments such

as untreated cotton may be particularly difficult to clean completely.

Suitability. Each item of protective clothing should be suitable for its circumstances of use. Respirators, in particular, should be of a type approved by a responsible authority. They should be fitted with the appropriate cartridge or filter to give protection against the particular hazard. There are many different types of respirator. These include

The safe use of respirators depends upon a thorough knowledge of

The user should receive specific training in all these aspects. There may be circumstances where there would be a choice of garments. These may include gauntlet gloves in preference to the shorter hand gloves, hats with broad rims or hoods, and goggles which are non-fogging. Advice should be sought.

Making a clean start. Clothing to be worn at the start of each day should be clean, dry and in good condition. The various items should be checked for signs of wear and tear and repaired or replaced as necessary.

Wearing correctly. When gloves are worn with an impermeable coverall, it is good practice to wear the cuffs of the gloves inside the shirt sleeves so that run-off of liquids sprayed does not drip inside the gloves. Similarly, the legs of coveralls should normally be worn outside boots so that run-off drips outside. Other garments should also be worn properly. This may include the correct fastening of buttons and zips and having face shields properly lowered into position (figure 39).

Figure 39. Protective clothing and

equipment

should be worn and used correctly

Decontamination after use. Gloves and boots should be washed before removal to avoid self-contamination (figure 40). They should then be removed and the inside should be thoroughly washed with water and detergent, rinsed and allowed to dry. Goggles and face masks should be similarly washed and allowed to dry.

Figure 40. Boots used during

agrochemical application

must be washed before removal to prevent contamination

Safe storage. Protective clothing should be stored in a clean, dry, well-ventilated room separate from other clothing or living accommodation (figure 41).

Figure 41. Protective clothing and

equipment

should be stored in separate accommodation

The FAO Guidelines for personal protection when working with pesticides in tropical climates (in preparation) will provide more detailed information.

2.4.4. The use of alternatives to agrochemicals

Good agricultural practice recognises the importance of agrochemicals. When used correctly, they contribute to an improvement in agricultural production. However, excessive or indiscriminate use of agrochemicals may lead to health hazards, and damage to crops, livestock, wildlife and the environment. Alternatives to a dependence on agrochemicals may include the following:

In some countries different control methods will be subject to national standards that regulate the way in which the controls may be used.

2.4.5. Prevention of poisoning

The prevention of poisoning depends upon a responsible attitude of the user under all circumstances of use. Before beginning agrochemical application the user should read, understand and follow the information on the label, check the suitability of equipment, and ensure that he or she has the necessary competence. The user's responsibility will end only after use. Every item used should be safely decontaminated and any surplus returned to the store. Taken together the precautionary measures may be summarised as follows:

2.5.2. Work in greenhouses and similar structures

There are special problems associated with work in greenhouses (figure 42), where agrochemicals are used in a wide variety of circumstances. These may include the controlled feeding of plants with liquid nutrients, or the release of carbon dioxide to assist plant growth or as pesticides for crop protection.

Figure 42. Work in a greenhouse involves many risks associated with agrochemicals

To some extent agrochemical use under a protective covering has advantages; the user is insulated against wind and other weather conditions. There are, however, disadvantages such as the following, which require special consideration:

Agrochemicals, particularly pesticides and . fertilisers, are sometimes applied from helicopters and fixed-wing aircraft (figure 43). This is a common practice in plantations in several countries. The national aviation authority that permits the use of these aircraft prescribes additional controls when they are used for aerial spraying. These requirements have already been published by the ILO. Some basic principles are listed in this guide.

Figure 43. Aerial spraying of pesticides

The national aviation authority should specify:

Discussion and activities

(sections 2.4 and 2.5)

1. Identify the safety devices on the equipment that you use for agrochemical spraying. List them separately.

2. List ten basic rules of personal hygiene.

3. Personal protective equipment

| Point to remember: Do not try to experiment unless you have received the correct advice. |

4. What is integrated pest control?

5. List eight precautionary measures you should take in organising the prevention of agrochemical poisoning.

6. If you have any experience of aerial spraying or working in greenhouses, explain to others in the group: