International

Labour Organization

Your health and safety at work

ERGONOMICS

III. Basic ergonomic principles

It is generally most effective to examine work conditions on a case-by-case basis when applying ergonomic principles to solve or prevent problems. Sometimes even minor ergonomic changes in the design of equipment, workstations (see section A, Workstation for more details about this topic) or job tasks can make significant improvements in worker comfort, health, safety and productivity. The following are a few examples of ergonomic changes which, if implemented, can result in significant improvements:

No matter what small or major ergonomic changes are discussed or implemented in the workplace, it is vital for the workers who will be affected by the changes to be involved in the discussions. Their input can be very helpful in determining what changes are necessary and appropriate. They know their job better than anyone else does. |

|

|

|

|

A workstation is the place a worker occupies when performing a job. The workstation may be occupied all the time or it may be one of several places where work is done. Some examples of workstations are work stands or work tables for machine operation, assembly or inspection; a work table where a computer is operated; a control console; etc.

A well designed workstation is important for preventing diseases related to poor working conditions, as well as for ensuring that work is productive. Every workstation should be designed with both the worker and the task in mind so that work can be performed comfortably, smoothly and efficiently.

If the workstation is properly designed, the worker should be able to maintain a correct and comfortable body posture. This is important because an uncomfortable work posture can cause a variety of problems, such as:

The main causes of these problems are:

The following are some basic ergonomic principles for workstation design. A general rule of thumb is to consider body size information, such as height, when choosing and adjusting workstations. Above all, workstations must be adjusted so that the worker is comfortable.

Workstation |

|

Head height

Shoulder height

Arm reach

Elbow height

Hand height

Leg length

Hand size

Body size

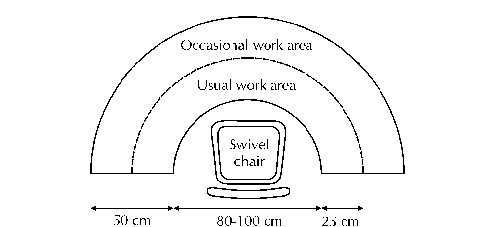

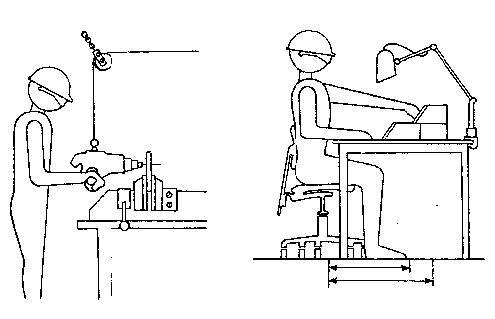

Two examples of good workstations |

|

Here are some general suggestions for an ergonomic workstation:

When you think about how to improve a workstation, remember this rule: If it feels right, it probably is right. If it feels uncomfortable, there is probably something wrong with the design, not the worker.

|

Points to remember about |

|

|

Sitting

If a job does not require a great deal of physical strength and can be done in a limited space,then the work should be done in a sitting position.

Note: sitting all day is not good for the body, especially for the back. Therefore, there should be some variety in the job tasks performed so a worker is not required to do sitting work only. A good chair is essential for sitting work. The chair should allow the worker to change the leg and general working positions easily.

The following are some ergonomic guidelines for sitting work:

The working position should be as comfortable as possible. The arrows indicate areas that need to be improved to prevent potential injuries from developing. To improve the sitting position for the worker on the right, the chair height should be lowered, tilted slightly forward and the worker should be provided with a footrest. |

|

The work chair

A proper work chair needs to satisfy certain ergonomic requirements. Use the following guidelines when choosing a chair:

On some jobs arm supports and rests may reduce arm fatigue.

Much of the above information may be somewhat idealistic for most workers, particularly workers in developing countries. However, it is essential that workers and their representatives understand that many health and safety problems are related to the non-application of ergonomic principles in the workplace. By understanding the importance of ergonomics, workers can start to improve their work situation, especially if management understands the relationship between productivity and good ergonomic conditions.

|

Points to remember about |

|

|

Standing for long periods of time to perform a job should be avoided whenever possible. Long periods of standing work can cause back pain, leg swelling, problems with blood circulation, sore feet and tired muscles. Here are some guidelines to follow when standing work cannot be avoided:

If a job must be done in a standing position, a chair or stool should be provided for the worker and he or she should be able to sit down at regular intervals.

A chair, footrest, a mat to stand on, and an adjustable work surface are essential components for a standing workstation. |

|

The job should be designed to allow the worker to keep the arms low and the elbows close to the body.

When determining the appropriate height of the work surface, it is important to consider the following factors:

Follow these guidelines to ensure a good body position for standing work:

|

Points to remember about standing workstations |

|

|

Hand tools

Hand tools should be designed according to ergonomic requirements. Poorly designed hand tools, or tools that do not fit the individual worker or the task can cause negative health effects and decrease a worker's productivity. In order to prevent health problems, as well as to maintain the worker's productivity, hand tools should be designed so that they fit both the individual and the task. Well designed tools can contribute to good body positions and movements and can increase productivity. Use the following guidelines when selecting hand tools:

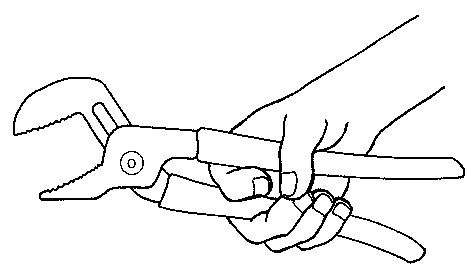

These pictures illustrate how tool design can prevent you having to work with a bent wrist. |

|

Do not use tools with spaces that can catch fingers or flesh. |

|

Controls

Control switches, levers, and knobs also need to be designed with the worker and the task in mind. Here are some guidelines for the design of controls:

|

Points to remember about |

|

|

Manual work must be designed properly so that workers will not overexert themselves and develop muscle strain, especially in the back. Performing heavy physical work for long periods causes the rate of breathing and the heart beat to increase. If a worker is not in good physical condition, he or she is likely to get tired easily while doing heavy physical work. Whenever possible, it is helpful to use mechanical power to do the heavy work. This does not mean that employers should replace workers with machines, rather, that workers can use machines to perform the most arduous tasks. Mechanical power reduces the risks to the worker and at the same time provides more work opportunities for people with less physical strength. Use the following guidelines for designing jobs that require heavy physical work:

Note: a job that requires no physical effort is just as undesirable as a job that only entails heavy physical work. Jobs that require no physical movement are generally tiring and boring.

To design a heavy physical job appropriately, it is important to consider the following factors:

The following are more detailed recommendations for heavy work, especially work that involves lifting. (See Appendix 1 at the back of this Module for guidelines on proper lifting and carrying techniques.)

Reduce the weight of the load:

Make the load easier to handle:

Use storage techniques to make handling materials easier:

Minimize the distance a load must be carried:

Minimize the number of lifts required:

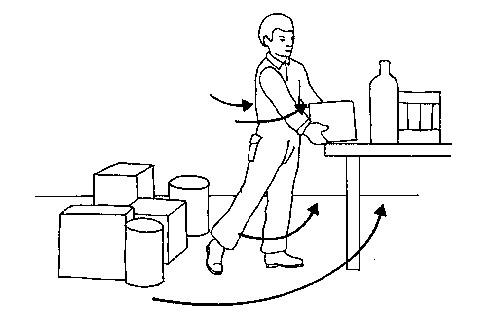

Minimize twisting of the body:

|

Points to remember about |

|

|

It is important to design jobs taking into consideration human factors. Well designed jobs consider the worker's mental and physical characteristics as well as health and safety conditions. The way a job is designed determines whether it is varied or repetitive, whether it allows the worker to be comfortable or forces him or her into awkward positions, and whether it involves interesting/stimulating tasks or boring monotonous ones. The following are some ergonomic factors that should be considered when designing or redesigning jobs:

Additionally, a well designed job should do the following:

|

Points to remember about |

1. Well designed jobs consider the worker's mental and physical characteristics as well as health and safety conditions. 2. Job design determines whether the work is varied or repetitive, whether it allows the worker to be comfortable or forces him or her into awkward positions, and whether it involves interesting/stimulating tasks or boring/monotonous ones. 3. There are a number of ergonomic factors that should be considered when designing or redesigning jobs, such as the type of tasks, how they need to be accomplished, and the type of equipment that is needed to complete the tasks. 4. A well designed job should allow a worker to vary the body position; it should include a variety of interesting tasks; give the worker some decision-making authority; provide a sense of accomplishment; include training for new job tasks; provide adequate work/rest schedules; and allow an adjustment period for new job tasks. |

|

IV. Role of the health and safety representative

As the health and safety representative you can play an important role in ensuring that ergonomics is used in the workplace. Your efforts to ensure that equipment and jobs are designed or adapted to fit workers will help to prevent a variety of health problems caused by poor working conditions.

Health and safety representative |

|

Remember: the goal of ergonomics is to look for ways to make the job fit the worker, instead of forcing the worker to conform to the job.

When trying to eliminate — or prevent — problems that may exist owing to the non-application of ergonomic principles, asking the following questions may help you to identify the cause of the problem:

(a) How well suited is the operator to his or her job, tools and workstation?

(b) How much time and effort does the worker spend on a particular task?

(c) How repetitive is the task?

Try to work together with the union, management and workers to implement ergonomic changes in the workplace. Use the health surveys and check-lists in the Appendices at the back of this Module to help you identify problem areas in your workplace. Then you can begin to establish priorities and work with the different groups to develop solutions. In many cases, you may have to think of ways to improve on an existing situation, since you may not, for example, have the luxury of getting new equipment which is designed according to ergonomic factors.

Remember: it is vital that the workers who will be affected by ergonomic changes — minor or major — are involved in discussions before changes are implemented. Their input can be very helpful in determining necessary and appropriate changes. They know their job better than anyone else does.

The following six points are a strategy which you as the health and safety representative can use to help workers win ergonomic improvements in the workplace.

Six-point strategy for winning ergonomic improvements in the workplace

Source: International Ladies' Garment Workers's Union, Health and Safety Department.

1. Reach out to other workers

Distribute copies of information factsheets or leaflets at work.

Listen to what others have to say about ergonomics-related issues.

Write down the names and work areas of people who are experiencing symptoms which you suspect may be caused by the non-application of ergonomic principles.

2. Collect information to identify problem areas

3. Study the areas you suspect are a problem

Walk through any problem areas and review the work tasks.

Start thinking of solutions, such as raising tables, rotating work, etc.

4. Gather recommendations from:

the workers who are affected;

maintenance and repair workers;

the union health and safety department (if one exists);

other health and safety specialists.

5. Push for necessary changes

Worker support (plus documentation) will give you the necessary encouragement for winning health and safety contract language, grievances, or other agreements with management.

6. Communicate with workers

Two-way communication is important in building and maintaining solidarity within the union.

| V. Summary | |

|

Ergonomics is a science which, when applied effectively, can lead to marked improvements in working conditions. Improvements can be made by properly designing or redesigning the way jobs are performed, the content of job tasks, the methods in which equipment is handled or set up, the way work schedules are set, the equipment used to perform a job, etc. Positive changes in these areas or others can help to prevent injuries and illnesses — physical or psychological — caused by a lack of attention to ergonomic principles in the workplace. Implementing ergonomic improvements does not have to be complicated or difficult. The union, workers and management should work together to assess priority problem areas and develop solutions. |

| Exercise. Identifying problems and developing solutions to ergonomic problems | |||||||||||||

|

Note to the instructor For this exercise, you will need a flipchart (or large pieces of paper taped to the walls) and markers, or a chalkboard and chalks. Give each trainee a copy of the action plan form. If you cannot make copies, then trainees can make their own action plans on a plain piece of paper. Put a copy of the six-point strategy for winning ergonomic improvements in the workplace (see p. 30) on the wall where everyone can see it. You may also want to give each participant a copy of the strategy. Instructions The first part of this exercise should be done in plenary or with the group as a whole. The second part will be a small group activity.

Try to plan enough time so that each group can present its Action Plan to the plenary.

Action plan for solving ergonomic problems in the workplace

|

||||||||||||

Appendix I. Lift and carry properly

Source: IMF Bulletin on Occupational Health and Safety, No. 19, 1985, Geneva, Switzerland.

Lift and carry properly

Lifting and carrying are physically strenuous, and there is always a risk of accidents and in particular of injury to the back and arms. To avoid this it is important to be able to estimate the weight of a load, the effect of the handling level and the lifting environment. You must also know how to choose a safe working method and how to use devices and equipment that make your work lighter.

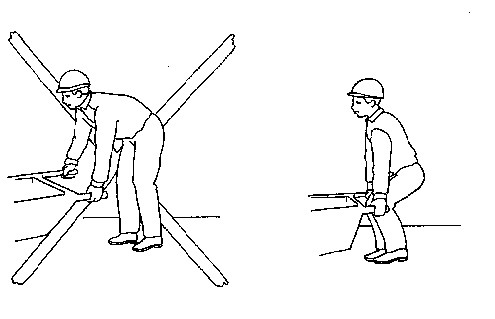

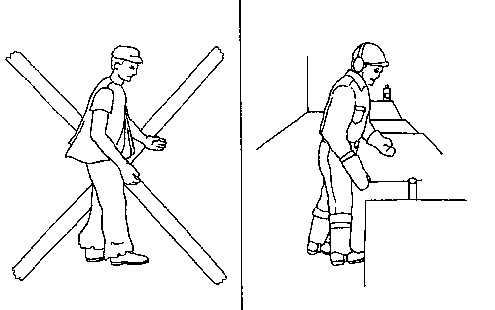

Position of the back and legs |

|

Lift the object close to your body, otherwise the muscles of the back and the ligaments stretch and the pressure in the intervertebral discs increases.

Tense your stomach and back muscles so that your back stays in the same position all the time you are lifting.

Position of the legs |

|

Stand close to the object. The closer you can get to the object, the safer it is to lift.

Keep your feet apart to maintain your balance well.

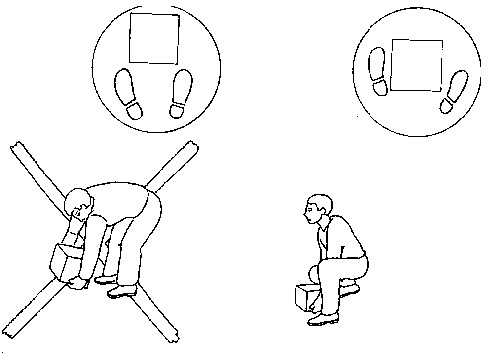

Position of the arms and grip |

|

Try to grasp the object firmly using your whole hands at right angles to your shoulder. You cannot get a firm grip using only your fingers.

Lift with both hands if possible.

Lifting to the side |

|

Lifting a weight and twisting the body at the same time increases the risk of back injury. Place your feet in a walking position, one foot pointing slightly in the direction of the lift. Lift the object and then shift the weight of the body onto the foot in the turning direction.

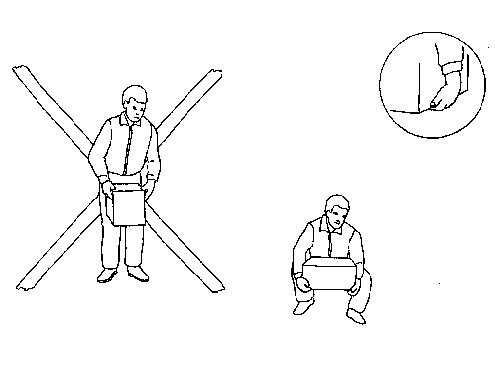

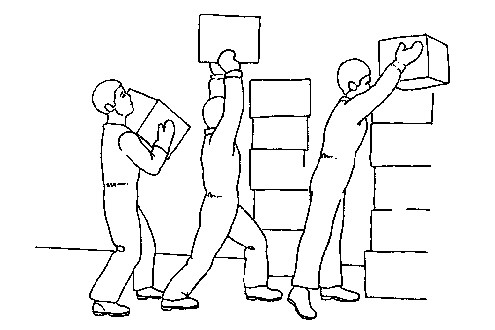

Lifting upwards |

|

If you have to lift something above shoulder level, place your feet in a walking position. First raise the object to chest level. Then begin pushing upwards by moving your feet out in order to get the object moving and shift the weight of your body onto the front foot.

For many people a suitable lifting height level is 70 to 80 centimetres. Lifting something off the floor can be three times as strenuous.

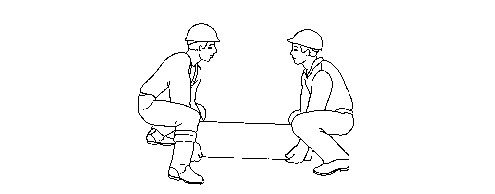

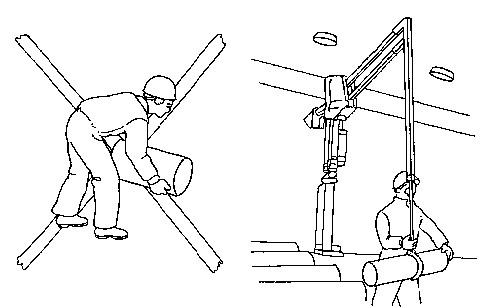

Lifting with others |

|

People who often lift things together should be more or less equally strong and they should practise lifting things together. The lifting movements must be made at the same time and at the same speed.

The maximum weights recommended by the International Labour Organization are:

Men: . . . . . . . . . . . . . . . . . . . . . occasionally 55 kg., repeatedly 35 kg.

Women: . . . . . . . . . . . . . . . . . . occasionally 30 kg., repeatedly 20 kg.

Do not lift anything if you have backache. Once the pain has gone, start lifting with caution and gradually practise.

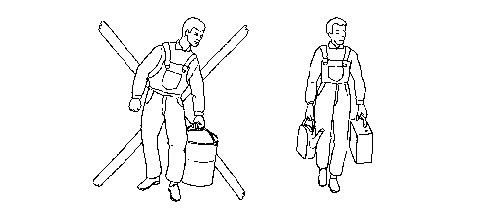

Carrying |

|

Carrying places most strain on the back of the neck and the upper limbs, the heart and the circulation. Carry objects close to your body. Minimum effort is then required to keep your balance and to carry the object. A round object is difficult to carry because the weight is far from the body. Good handles or grips make the work easier and bring additional safety. Spread the weight evenly over both hands.

Carrying is always strenuous. Check whether the object can be shifted on a conveyor belt, wheels or a trolley. Make sure you do not try to shift an object that is too heavy on your own, that there are proper hand grips, that the hand grips are at a suitable distance, that there is room to lift and carry the object, that the floor is not slippery, that there are no obstacles in your way and that there is sufficient lighting. Unless well designed, steps, doors and ramps are dangerous.

Clothing |

|

Your clothing should regulate the temperature between the air and the heat generated by you body. Clothes must not be so loose, or so long or flapping as to be dangerous. Gloves should protect your hands and help you to get a good grip. Footwear should be sturdy, non-slippery and have broad soles. The uppers should protect your feet from falling objects. A helmet is essential for mechanical lifting. The helmet must be firmly fastened so that it cannot fall off at the vital moment or obstruct your view. A wide belt giving the back support (a weightlifter's belt) may be useful.

Auxiliary devices |

|

Devices used to make your work easier must be light and easy to use, in order to reduce exertion and the risk of accidents. For example, magnets, eccentric and lever grabs, suction cups, carrying frames, such as yokes and backpacks, give you a good grip on the load and improve your working position. Trolleys, lifting tables, roller and disc conveyors and conveyor belts reduce shifting work.

Appendix II. Job design check-list

Source: United Auto Workers' Union

| Difficult work positions | |

| Can the time spent in one position (sitting, standing, bending, twisting) be reduced by redesigning the job, providing rest breaks, rotating workers, or providing chairs or stools? | |

| Can the work height be adjusted? For example, can an adjustable table or counter be provided so that each worker can adjust it for his or her height and for sitting or standing? | |

| Can adjustable chairs be provided? | |

| Can machine controls or materials be placed so workers can reach them more easily? | |

| Mental stress | |

| Can workers who must maintain close concentration be given extra breaks? | |

| Can employees who work alone be rotated to other jobs for part of the shift to alleviate feelings of isolation? Can workers who deal with the public spend part of their day doing other kinds of work? | |

| Can workers have more control over the pace of work? For example, could custodians be told what needs to be done during a given week and then be allowed to determine how and when the work is performed? | |

| Can the quota of work for each person be adjusted to a more realistic level? | |

| Stress from the work environment | |

| Can sources of noise and vibration be removed or controlled? For example, a noisy motor or generator which causes stress for nearby workers might be enclosed or moved to a remote location. | |

| Can chemical hazards that cause headaches or minor irritations be controlled? | |

| Can lighting be improved? | |

| Can workers be given control over the temperature in their work environment? | |

| Tools and machinery design | |

| Can tools be designed to eliminate twisting of the hand or wrist? | |

| Can trucks or other machinery be designed so the driver or operator has a clearer view? | |

| Can gauges be made easier to read? | |

| Can machinery be used to lift heavy loads instead of moving them by hand? For example, in hospitals, slings and other equipment can be used to help lift patients. |

Appendix III. What do you do if you think you have a cumulative trauma disorder?

Source: International Ladies Garment Workers' Union, Health and Safety Department.

Notify your employer

Do this with a witness or in writing and keep a copy for yourself.

See a doctor as soon as possible

Because cumulative trauma injuries develop slowly, workers often ignore the symptoms until they become severe. By that time, the injury may be permanent. Make sure you explain to your doctor the type of work you do.

Document

Keep notes of the events related to this injury, including whom you spoke to and when, as well as all medical expenses related to the injury and any conversations with or correspondence from your employer. These notes could be invaluable if a dispute arises regarding your injury.

Contact your union for assistance

Appendix IV. Evaluate your job for risk factors

Does your job require you to:

All of the above are “risky positions” that can lead to the development of repetitive strain injuries. If you answer “yes” to any of the questions above, tell your union and your employer.

Appendix V. Controlling vibration hazards; health survey: whole-body vibration and hand-arm vibration

Source: Guidelines on hazards of vibration, Australian Council of Trade Unions.

Fit the job to the worker

Controlling vibrating hazards

|

Health survey: whole-body vibration Personal description (if you want to give it) Name .................................................................................................................................... Age ....................................................................................................................................... Male ........................................................ Female ................................................................ Job description Present job title....................................................................................................................... When did you start on this job?............................................................................................... What vibrating equipment do you use?..................................................................................... For how long each day? ........................................................................................................... Past jobs where vibration was a factor: ....................................................................................... Length of time employed ......................................................................................................... Machines or tools used .............................................................................................................. Health description If you are exposed to mainly whole-body vibration (near machines, concrete vibrators, buses, trucks, tractors, etc.) do you or have you suffered from:

For each problem ticked indicate: A for All the time R for Regularly O for Occasionally Did you suffer from any of these complaints before you started your present job? If yes, please give details: .......................................................................................................................... .............................................................................................................................................. Any other comments? ........................................................................................................... ............................................................................................................................................... |

Health survey: hand-arm vibration Personal description (if you want to give it) Name .................................................................................................................................... Age ....................................................................................................................................... Male ........................................................ Female ................................................................ Job description Present job title....................................................................................................................... When did you start on this job?............................................................................................... What vibrating equipment do you use?..................................................................................... For how long each day? ........................................................................................................... Past jobs where vibration was a factor: ....................................................................................... Length of time employed ......................................................................................................... Machines or tools used .............................................................................................................. Health description If you are exposed mainly to hand-arm vibration (from pneumatic tools, chain-saws, grinders, etc.) do you or have you suffered from:

For each problem ticked indicate: A for All the time R for Regularly O for Occasionally Did you suffer from any of these complaints before you started your present job? If yes, please give details: .......................................................................................................................... .............................................................................................................................................. Any other comments? ........................................................................................................... ............................................................................................................................................... |